Extraction of teeth requires specific skills, expertise, and correct armamentarium. Oral surgery instruments include elevators, Luxating forceps, Periotomes, and Extraction forceps. Forceps are instruments that grasp the tooth and remove them out of their sockets. These dentistry instruments are designed in various styles and shapes to accommodate a variety of teeth. One of these forceps is the Bird beak extraction forceps, discussed below.

Instrument Components:

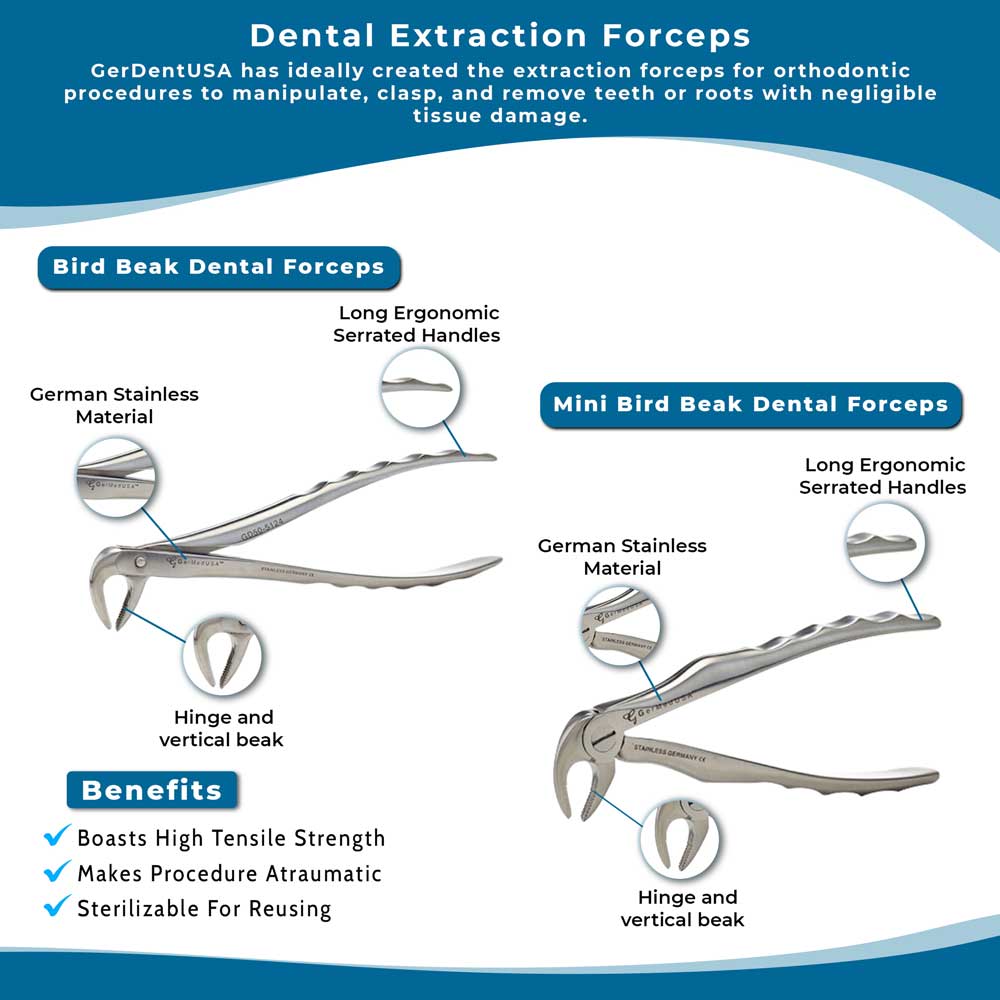

The design of oral surgery forceps includes a handle, hinge, and beaks. The handles are for the operator to grasp the instrument. These forceps are sometimes serrated to allow for good control of the instrument. For extraction of maxillary teeth, the operator's palm is under the handle of the instrument. For mandibular teeth, the palm is on top of the instrument. The handle designs may be straight or curved. Curved handles sometimes provide the operator with a better sense of “fit.”

The hinge is the part of the Forceps that concentrates the force applied to the beaks.

The beaks of every Forceps are concave on the inner side to fit around the tooth to be extracted. Beaks are designed to adapt to the tooth, where the crown meets the root.

Use of the Bird Beak Extraction Forceps:

The Bird beak forceps are instruments that extract the mandibular anterior teeth and premolars. The instrument's design is such that there is a small space between the two beaks of the instrument. It allows good grasping of the teeth. These forceps are made from high-quality stainless steel. Stainless steel instruments are reusable after sterilization.

Types of Forceps:

There are two common types of oral surgery extraction forceps- American patterned and English patterned forceps. The main difference between the two lies at their hinges.

American patterned forceps feature a horizontally directed hinge from the handles. Whereas the English patterned Bird beak forceps include a visible screw and fulcrum closer to the beaks/ working end of the instrument. The hinge for the English patterned Forceps is directed vertically to the handles of the instrument. Other than that, maxillary and mandibular forceps are the other two types also available.

Manufacturing Material:

Stainless steel is tough and resilient. It has excellent corrosion resistance properties and offers good aesthetics. It is an ideal material for surgical instrument manufacture. Stainless steel has an excellent strength-to-weight ratio. Instruments are lightweight and possess good strength.

Stainless steel instruments can be used with force without inflicting any damage to the instrument itself. Forceps have to be in the clinician's hand for more extended periods. A lightweight instrument prevents fatigue in the operator's arm.

Apart from that, Stainless steel dental instruments are reusable. Once Forceps are used on a patient, It is easily sterilizable and can be used on another patient. Hence, stainless steel is an excellent choice for Bird beak dental Forceps manufacturing

Sterilization Process:

Sterilization is a critical step for instrument reuse. Instruments used in dentistry need efficient cleaning techniques for effective decontamination. Forceps are first manually cleaned for the removal of debris.

These dental tools then require immersion in a disinfectant. After disinfection, instruments are packaged into sterilizable pouches for sterilization in the autoclave.

Steam sterilization is the most convenient and effective way to sterilize stainless steel equipment such as extraction forceps. Forceps are critical instruments. These penetrate through the mucosa, deep in the alveolar bone, and hence these tools need the highest level of sterilization.

Critical instruments have the greatest risk of transmitting infections. The manufacturer's instructions should be followed throughout the process of sterilization. It prevents instruments from unnecessary damage. For example, Sometimes, the manufacturer may need you to disassemble instruments before processing them in the autoclave. Hence following these instructions is essential to prevent possible cross-infection.

Customization of Instruments:

We offer customization of instruments. Dental surgical instruments come in a variety of designs. Different operators prefer different instruments. Hence, we are offering customization of instruments for all practicing doctors who may find available instruments unfit for practice.

We encourage such practicing professionals to come up with innovative designs for customization. We believe it will benefit the healthcare market today and in the future. We aim to serve the healthcare market today and in the future by delivering excellent quality Surgical equipment for use.